Overview of Instrumentation Services

- Overhaul, servicing & testing of mechanical ball valves, control valves, choke valves, gate valves

- Overhaul, servicing, calibration & testing of pressure relief valves & pressure vacuum valves

- Inspection, servicing, repair, overhaul and testing of pneumatic / hydraulic actuators, electric / electro-pneumatic valve actuators

- Design, engineering, manufacture, assembly, inspection, testing & integration of wellhead control panels (whcp) & wellhead control modules (wcm)

- Design, engineering, fabrication, testing & integration of pneumatic / instrument control panels ( such as: siprod, gaslift, deluge, kill knob, audible alarm, trunk line, interface, etc.)

- Design, engineering, manufacture, assembly, inspection, testing & integration of chemical injection skid

- Servicing, overhaul, calibration & testing of pneumatic / electronic gauges, switches, transmitters, recorders & controllers (pressure, flow, temperature & level)

- Preventive & corrective maintenance of fire & gas detection system

- Service, repair, calibration, testing & validation of portable / personal type gas detectors

- Supply of skilled instrument / electrical personnel

- Supply of skilled instrument personnel

- Provide project site installation as per client’s request

MAIN SERVICES

Design, engineering, fabrication, testing & integration of:

- Wellhead Control Panels (WHCP)

- SIPROD Control Panels

- Gaslift Control Panels

- Deluge Control Panels

- Kill knob Panels

- Audible Alarm Control Panels

- Trunk Line Control Panels

- Interface Control Panels

Panel Enclosure can be fabricated to meet IP (Ingress Protection) rating as per client’s requirement.

We also provide Onsite Survey, Refurbishment & Commissioning Services

Overhaul, servicing & testing of:

- Pneumatic / Hydraulic Shutdown Valves

- Control Valves (Pressure, Flow, Level)

- Gate Valves

- Motor Operated Valves

- Choke Valves

- Safety Relief Valves

- Pressure Vacuum Valves

- Pneumatic / Hydraulic Actuators

- Electro-Pneumatic Valve Actuators

Valves are tested to API 6D, API 598 standards

Servicing, overhaul, calibration & testing of:

- Gauges ( Pressure / Flow / Temperature / Level )

- Pneumatic / Electronic Switches

- Pneumatic / Electronic Controllers

- Pneumatic / Electronic Transmitters

- Pneumatic / Electronic Recorders

Calibration & Testing Laboratory Equipment is traceable to SIRIM standards

Other Services

- Preventive & Corrective Maintenance of Fire & Gas Detection System

- Service, repair, testing, calibration & validation of various types of gas detectors

- Design, engineering, manufacture, assembly, inspection, testing & integration of chemical injection skid

- Supply of skilled instrument personnel

- Provide project site installation as per client’s request

- Acoustic valve leak inspection using MIDAS Meter (see below)

MIDAS METER

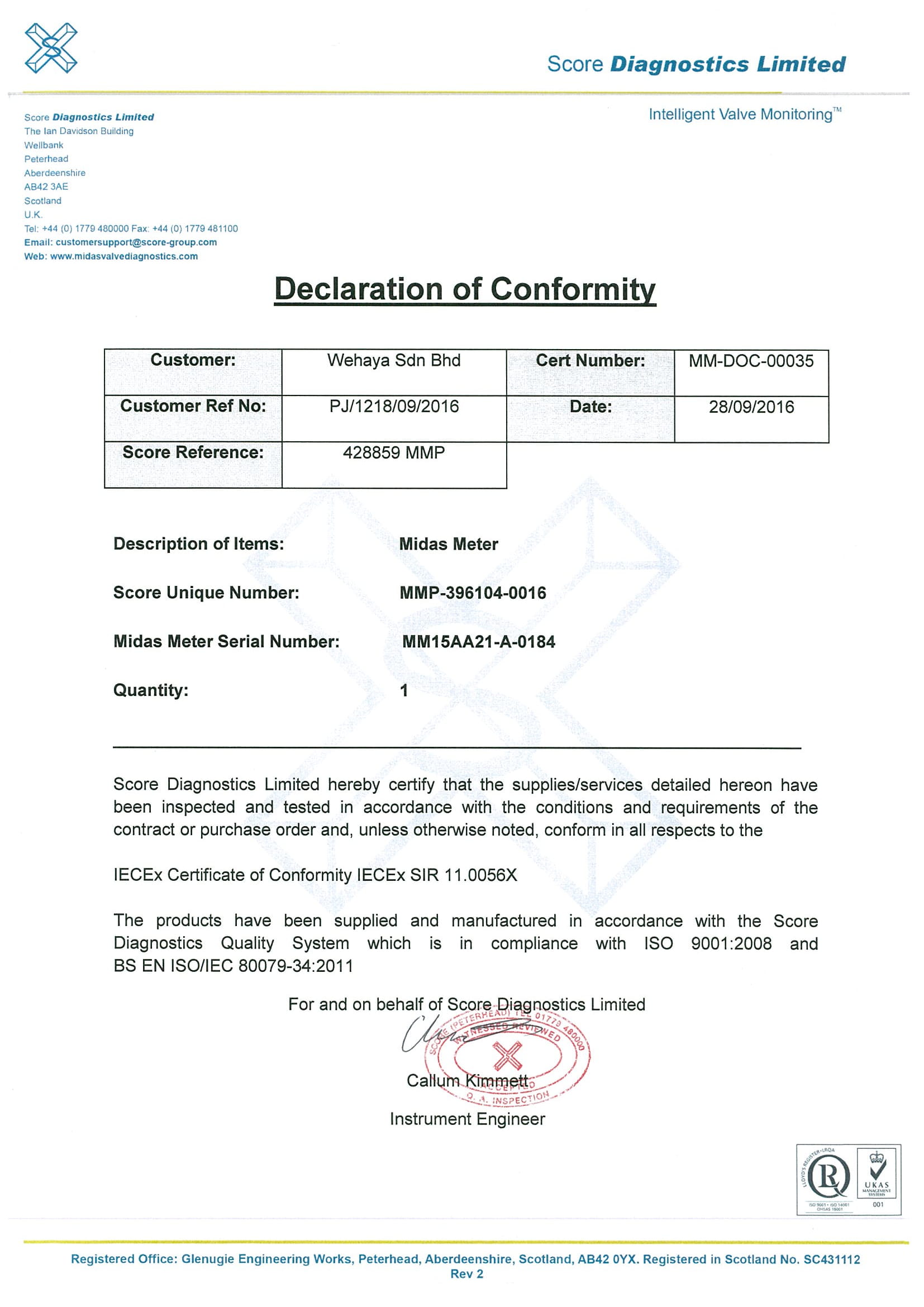

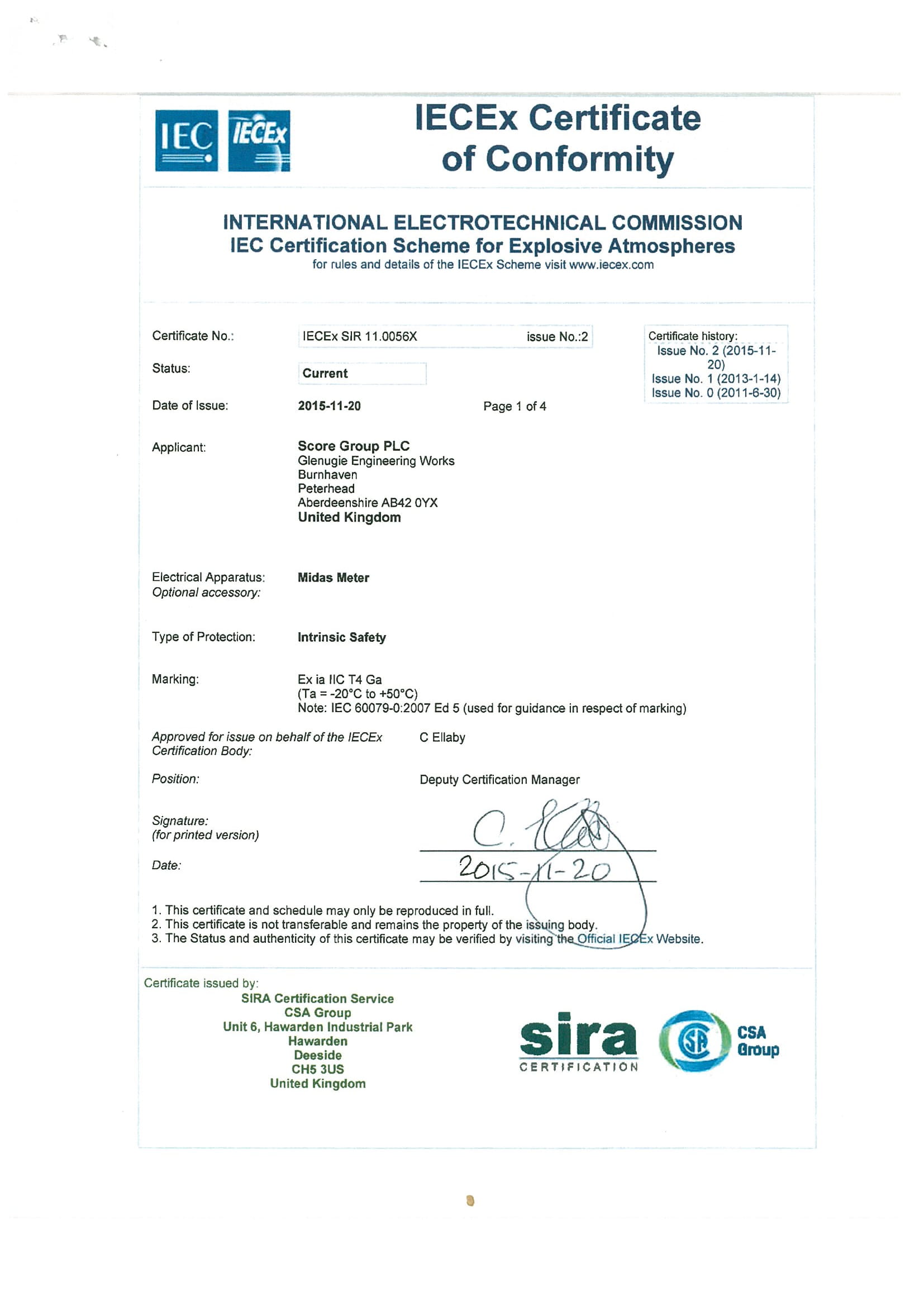

The MIDAS Meter is the latest equipment utilised by Wehaya Sdn Bhd to perform acoustic valve leak inspection. The purpose of acoustic valve leak inspection is to detect passing valves and measure the valve passing (leak) rates. The MIDAS Meter is specifically designed to pick up ultrasonic noises emitted by a passing valve from its valve body. The MIDAS Meter PDA software enables it to convert the noise readings instantaneously into a valve leak rate reading. The MIDAS Meter can detect valve leak rates as low as 0.1 std L/min. It is rated intrinsically safe and is non-intrusive to the process system, making it the acoustic equipment of choice for its intended application.

The MIDAS Meter consists of a handset, a PDA and accessories. Both have been rigorously tested to ensure compliance with global standards for electrical equipment required to operate in hazardous areas and harsh environments. The MIDAS Meter is certified safe to use globally in hazardous and non-hazardous process areas.

The advantages of the MIDAS Meter over other acoustic equipment are as follows:

- All equipment and accessories are contained within a durable and portable hand-carry case

- Easy to set up and detect ultrasonic noises emitted by passing valves

- Provides instantaneous valve leak rate readings to the user on-site

- The acoustic valve leak inspection results are easy to understand and interpret

- Able to plot the acoustic valve leak inspection results in the form of tables and charts using the MIDAS Meter PC software

- Calibrated once a year to prevent handset sensor drift and to incorporate software updates

In addition to the above, Wehaya Sdn Bhd can provide solutions to rectify passing valves:

- Provide service recommendations to the client for passing valves in the form of corrective maintenance (sealant injection), overhaul and refurbishment, or replacement

- Able to perform sealant injection on passing valves on-site

- Able to use the MIDAS Meter to determine whether the valve is still passing after performing sealant injection. If the valve is still passing, continue to perform sealant injection on the valve until the valve is no longer passing.